Pharmaceuticals and Active Pharmaceutical Ingredients (APIs)

Pharmaceuticals play a crucial role in modern healthcare by providing treatments for a wide range of diseases and medical conditions. These medicinal products consist of active and inactive ingredients, with the Active Pharmaceutical Ingredients (APIs) being the essential components responsible for the therapeutic effects. APIs are combined with excipients (inactive substances) to form the final pharmaceutical product, such as tablets, capsules, injectables, or topical applications.

Understanding Active Pharmaceutical Ingredients (APIs)

APIs are the biologically active components of a drug formulation that interact with the body to produce the desired medical effect. They are responsible for diagnosing, treating, mitigating, preventing, or curing diseases. APIs can be derived from various sources, including chemical synthesis, biotechnology, fermentation, or natural extraction from plants and animals.

APIs are classified into two main categories:

Synthetic APIs: These are chemically synthesized in laboratories through complex chemical reactions. They are widely used in various therapeutic areas, including cardiovascular, oncology, and pain management drugs.

Biological APIs (Biologics): Derived from living organisms, these include proteins, antibodies, and vaccines. Biologics are used in treating conditions such as autoimmune diseases, cancer, and infectious diseases.

The API Manufacturing Process

The production of APIs involves a series of stringent processes to ensure their quality, safety, and efficacy. The key stages of API manufacturing include:

Raw Material Selection: High-quality raw materials are chosen to ensure the purity and effectiveness of the final API.

Chemical Synthesis or Biotechnological Production: APIs are synthesized through chemical processes or produced using biotechnological methods, such as recombinant DNA technology or fermentation.

Purification and Isolation: The synthesized API is purified through techniques like crystallization, chromatography, and filtration to remove impurities.

Quality Control and Testing: Rigorous analytical testing ensures that the API meets regulatory and pharmacopoeial standards before formulation.

Final Processing and Packaging: The API is processed into a stable form (powder, granules, or liquid) and packaged for transportation to pharmaceutical companies.

Pharmaceutical Formulations and Drug Development

Pharmaceutical formulations are created by combining APIs with excipients, which aid in drug delivery, stability, and absorption. The choice of formulation depends on factors such as drug solubility, bioavailability, and patient compliance.

Common pharmaceutical dosage forms include:

Oral (Tablets, Capsules, Syrups): The most common route, ensuring convenience and patient adherence.

Injectable (Intravenous, Intramuscular, Subcutaneous): Used for rapid drug action in critical care and chronic diseases.

Topical (Creams, Ointments, Gels): Applied to the skin for localized treatment.

Inhalation (Nebulizers, Inhalers): Used for respiratory conditions such as asthma and COPD.

Transdermal (Patches): Provide sustained drug release through the skin.

Regulatory and Quality Assurance in API Production

API manufacturing is highly regulated to ensure safety, efficacy, and quality. Regulatory authorities such as the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and World Health Organization (WHO) set strict guidelines for API production.

Key regulatory aspects include:

Good Manufacturing Practices (GMP): Ensures proper documentation, validation, and hygiene standards.

Pharmacopoeial Standards: APIs must comply with standards outlined in the United States Pharmacopeia (USP), European Pharmacopoeia (EP), and Indian Pharmacopoeia (IP).

Stability Testing: Evaluates the API’s shelf-life and degradation under different conditions.

Supply Chain Transparency: Ensures traceability and authenticity to prevent counterfeit drugs.

The Global API Market and Challenges

The global API market is expanding due to increased pharmaceutical demand, advancements in drug research, and the rise of chronic diseases. Major API manufacturers are based in India, China, the United States, and Europe, with India and China being dominant players due to cost-effective production capabilities.

Challenges faced in API production include:

Regulatory Compliance: Meeting stringent regulatory requirements increases costs and complexity.

Supply Chain Disruptions: Dependence on raw material imports can cause delays and shortages.

Environmental Concerns: Waste disposal and pollution from chemical synthesis raise sustainability issues.

Counterfeit APIs: The risk of substandard or fake APIs entering the market is a significant challenge.

Future Trends in API Development

Innovations in API manufacturing are driving the pharmaceutical industry towards more efficient and sustainable production methods. Key trends include:

Green Chemistry Approaches: Eco-friendly synthesis methods to reduce environmental impact.

Biopharmaceuticals and Biosimilars: Growth in biologic drug production, including gene and cell therapies.

Personalized Medicine: APIs tailored to individual genetic profiles for enhanced treatment efficacy.

Continuous Manufacturing: Advanced production techniques to improve efficiency and reduce costs.

Conclusion

Pharmaceuticals and APIs are integral to modern medicine, enabling the treatment and prevention of diseases worldwide. With advancements in technology and stringent regulatory oversight, the industry continues to evolve, ensuring the availability of safe and effective medications. As research progresses, the future of APIs will likely see enhanced sustainability, innovation, and improved accessibility, benefiting patients globally.

Our Products

-

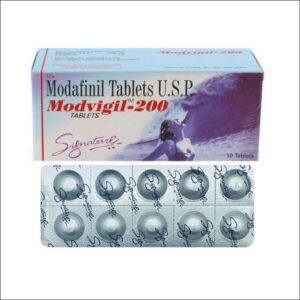

Modafinil-200mg

$2.00 / Per Pill

-

Ivermectin 12MG

$2.00 / Per Pill

-

Prednisone 10MG

$0.80 / Per Pill